FOUTZ

& BURSUM

FOUTZ

& BURSUM

Home Construction & Maintenance Dry Ice Blasting Fabrication Roustabout Services Projects Contact Us

Dry Ice Blasting Cleaning

Dry ice blasting is similar to sand blasting, plastic bead blasting or soda blasting, but much more cost efficient.

Instead of using hard, abrasive media

to grind on a surface (and damage it), dry ice blasting uses soft dry ice, accelerated at

supersonic speeds, and creates mini-explosions on the surface to lift the undesirable

items off the underlying substrate. Soft and sensitive materials can be cleaned without

damage. The dry ice evaporates so there is no blast media cleanup.

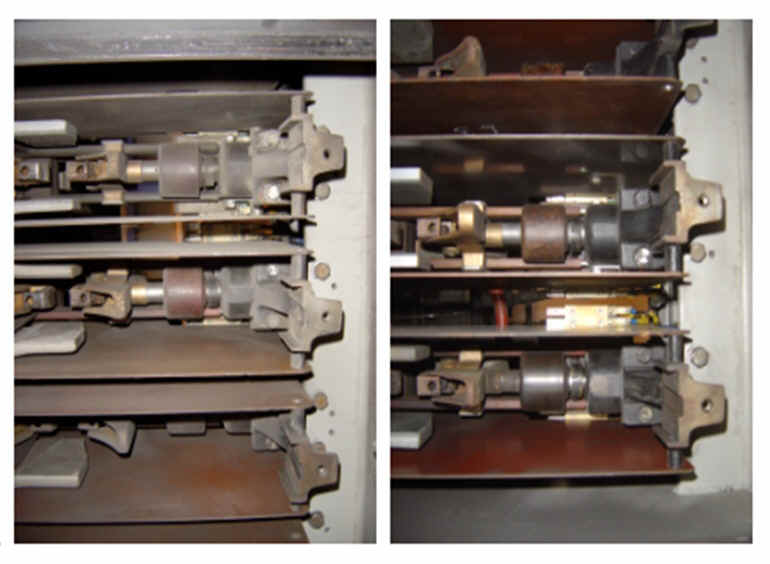

Before

and after dry ice blasting:

Some

of the benefits of Dry Ice Blast Cleaning include enhancing operator safety and health,

reduce labor costs, effective cleaning without having to disassemble, and reduction or

elimination of production downtime.

Applications include paint removal; weld blasting for inspections, and commercial use. Commercial use includes cooling tubes, fin fans, sulfur buildup removal, delicate chrome or nickel plated tools, copper, cleaning compressors while in service, and soft aluminum or brass alloys.

From set-up to clean-up, dry ice is faster and provides better results which also means less downtime for you and more money making it to your bottom line.